“Unlock the Power of C12 steel grade: Discover Its Chemical Properties, Composition, and Mechanical Equivalents!”

Exploring the Chemical Properties of C12 Steel Grade

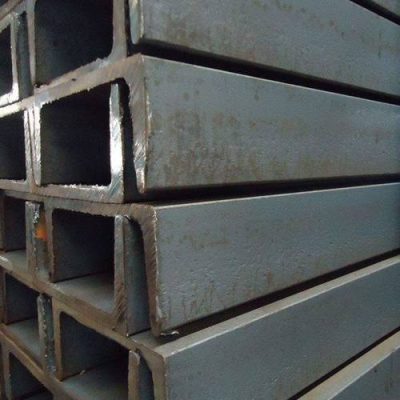

C12 steel grade is a low-alloy steel that is commonly used in the construction of industrial and commercial structures. It is composed of a combination of iron and carbon, and is known for its strength and durability. This steel grade is also highly resistant to corrosion and has excellent weldability.

The chemical composition of C12 steel grade is as follows: Carbon (C) 0.12-0.20%, Manganese (Mn) 0.30-0.60%, Phosphorus (P) 0.040%, Sulfur (S) 0.040%, Silicon (Si) 0.15-0.30%, Chromium (Cr) 0.40-0.60%, Nickel (Ni) 0.30-0.50%, Molybdenum (Mo) 0.15-0.25%, and Vanadium (V) 0.08-0.15%.

The mechanical properties of C12 steel grade are as follows: Tensile Strength (MPa) ≥520, Yield Strength (MPa) ≥340, Elongation (%) ≥17, Hardness (HB) ≤187, and Impact Value (J) ≥27.

The physical properties of C12 steel grade are as follows: Density (g/cm3) 7.85, Melting Point (°C) 1420-1460, Thermal Conductivity (W/mK) 45.7, Specific Heat (J/kgK) 0.48, and Electrical Resistivity (μΩm) 0.14.

C12 steel grade is a versatile material that can be used in a variety of applications. It is highly resistant to corrosion and has excellent weldability, making it ideal for use in the construction of industrial and commercial structures. Its mechanical properties make it suitable for use in applications that require strength and durability. Additionally, its physical properties make it suitable for use in applications that require thermal and electrical conductivity.

Understanding the Composition of C12 Steel Grade

C12 steel grade is a low-alloy carbon steel that is commonly used in the manufacturing of various industrial components. It is composed of a combination of iron and carbon, with a carbon content of 0.12-0.20%. The addition of carbon to the iron increases the strength and hardness of the steel, making it suitable for use in a variety of applications.

C12 steel grade is composed of a number of alloying elements, including manganese, silicon, phosphorus, sulfur, and chromium. These elements are added to the steel in order to improve its mechanical properties, such as its strength, toughness, and ductility. The addition of manganese and silicon increases the steel’s strength and hardness, while the addition of phosphorus and sulfur increases its machinability. The addition of chromium increases the steel’s corrosion resistance.

C12 steel grade is typically used in the manufacturing of components that require high strength and toughness, such as gears, shafts, and fasteners. It is also used in the production of springs, wire ropes, and other components that require high levels of corrosion resistance.

Overall, C12 steel grade is a versatile and reliable material that is suitable for a variety of industrial applications. Its combination of strength, toughness, and corrosion resistance make it an ideal choice for many components.

Analyzing the Mechanical Properties of C12 Steel Grade

The mechanical properties of C12 steel grade are important for determining its suitability for various applications. This steel grade is a low-carbon steel that is commonly used in the construction of bridges, buildings, and other structures. It is also used in the manufacture of automotive components and machine parts.

The mechanical properties of C12 steel grade include its tensile strength, yield strength, and elongation. The tensile strength of C12 steel grade is typically between 400 and 500 MPa. This indicates the steel’s ability to resist breaking under tension. The yield strength of C12 steel grade is typically between 250 and 350 MPa. This indicates the steel’s ability to resist deformation under load. The elongation of C12 steel grade is typically between 20 and 30%. This indicates the steel’s ability to stretch before breaking.

In addition to these mechanical properties, C12 steel grade also has good weldability and machinability. It can be welded using conventional welding techniques and can be machined using standard machine tools.

Overall, C12 steel grade is a versatile material that is suitable for a wide range of applications. Its mechanical properties make it an ideal choice for structural applications, while its weldability and machinability make it suitable for use in the manufacture of automotive components and machine parts.

Comparing the Equivalent Grades of C12 Steel Grade

The C12 steel grade is a structural steel grade that is widely used in the construction industry. It is a low-carbon steel grade that is highly ductile and has excellent weldability properties. It is also known for its good machinability and formability properties. The C12 steel grade is equivalent to the following grades: ASTM A576, ASTM A29, SAE J403, SAE J412, SAE J414, and DIN 17222. All of these grades have similar mechanical properties and are suitable for use in the construction industry. The C12 steel grade is also equivalent to the following grades: BS 970 080M15, BS 970 070M20, BS 970 080M30, BS 970 080M40, and BS 970 080M50. These grades are all low-carbon steel grades that are highly ductile and have excellent weldability properties. They are also known for their good machinability and formability properties.

Examining the Benefits of Using C12 Steel Grade in Manufacturing

C12 steel grade is a low-alloy steel that is commonly used in the manufacturing industry. It is a versatile material that offers a range of benefits, including excellent weldability, good machinability, and high strength. This article will examine the advantages of using C12 steel grade in manufacturing.

One of the primary benefits of C12 steel grade is its weldability. This steel grade has a low carbon content, which makes it easier to weld than other steel grades. It also has a low sulfur content, which helps to reduce the risk of weld defects. Additionally, C12 steel grade has a high tensile strength, which makes it suitable for use in applications that require strong welds.

Another advantage of C12 steel grade is its machinability. This steel grade has a low carbon content, which makes it easier to machine than other steel grades. It also has a low sulfur content, which helps to reduce the risk of tool wear. Additionally, C12 steel grade has a high hardness, which makes it suitable for use in applications that require precise machining.

Finally, C12 steel grade has a high strength-to-weight ratio. This means that it is lightweight yet strong, making it suitable for use in applications that require a strong yet lightweight material. Additionally, C12 steel grade has a high fatigue strength, which makes it suitable for use in applications that require components that can withstand repeated stress.

In conclusion, C12 steel grade is a versatile material that offers a range of benefits, including excellent weldability, good machinability, and high strength. It is suitable for use in a variety of applications, including those that require strong welds, precise machining, and lightweight yet strong components.