-

Table of Contents

- How Galvanized Steel Coils Can Improve Automotive Manufacturing Efficiency

- The Advantages of Galvanized Steel Coils for Automotive Manufacturing

- The Benefits of Galvanized Steel Coils for Automotive Durability

- The Cost Savings of Galvanized Steel Coils for Automotive Manufacturing

- The Corrosion Resistance of Galvanized Steel Coils for Automotive Manufacturing

- The Strength and Durability of Galvanized Steel Coils for Automotive Manufacturing

- The Versatility of Galvanized Steel Coils for Automotive Manufacturing

- The Environmental Benefits of Galvanized Steel Coils for Automotive Manufacturing

- Conclusion

“Galvanized Steel Coils: Automotive Manufacturing’s Best Kept Secret for Durability and Performance!”

How Galvanized Steel Coils Can Improve Automotive Manufacturing Efficiency

Galvanized steel coils are an essential component of automotive manufacturing, providing the strength and durability needed to produce high-quality vehicles. By utilizing galvanized steel coils, automotive manufacturers can improve their efficiency and reduce costs.

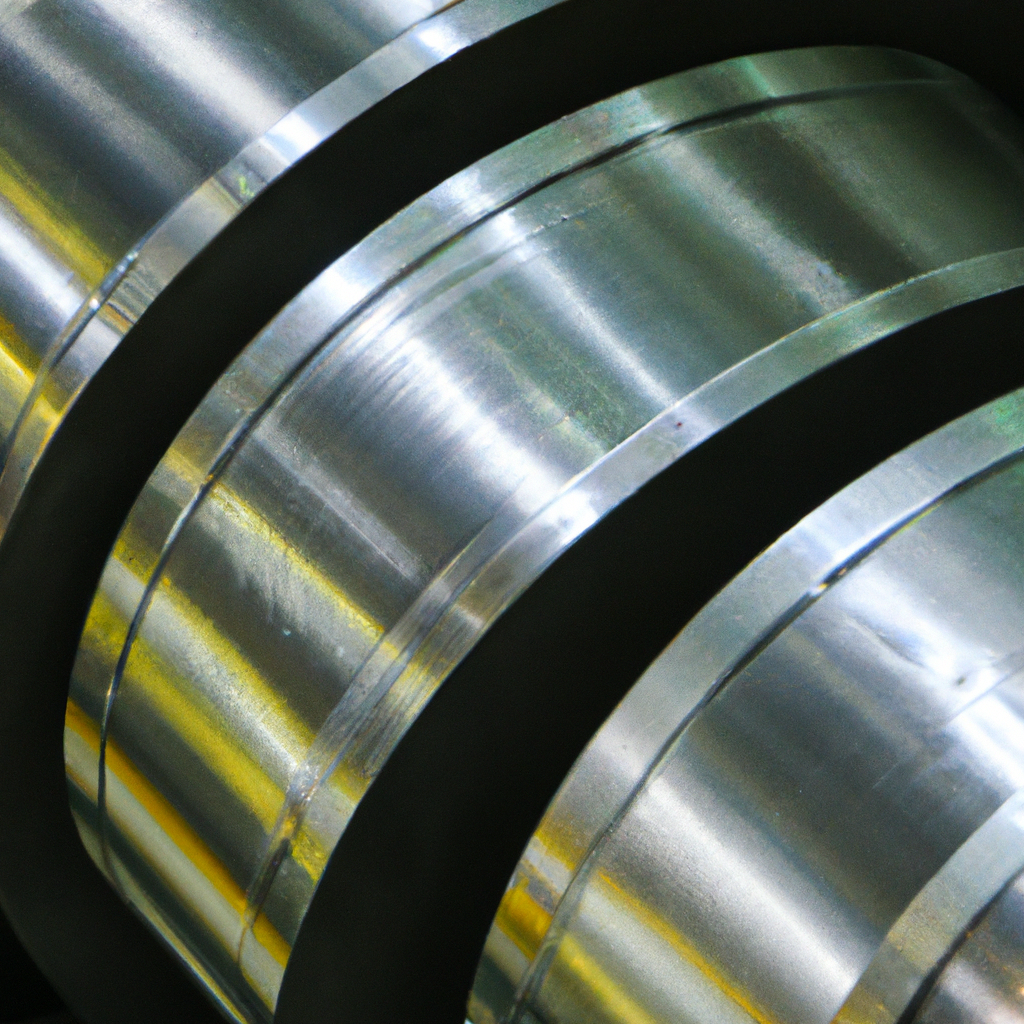

Galvanized steel coils are made by coating a thin layer of zinc onto steel, which provides a protective layer that prevents corrosion and rust. This layer of protection is especially important in automotive manufacturing, as it helps to ensure that the parts produced are of the highest quality and will last for years to come.

The use of galvanized steel coils also helps to reduce costs associated with automotive manufacturing. By using galvanized steel coils, manufacturers can reduce the amount of time and money spent on painting and other finishing processes. Additionally, galvanized steel coils are more durable than other types of steel, meaning that they require less maintenance and repair over time. This can help to reduce the overall cost of production.

Finally, galvanized steel coils are also more efficient than other types of steel. They are able to withstand higher temperatures and pressures, meaning that they can be used in a variety of manufacturing processes. This can help to reduce the amount of time and energy needed to produce parts, resulting in a more efficient production process.

Overall, galvanized steel coils are an essential component of automotive manufacturing. By utilizing galvanized steel coils, automotive manufacturers can improve their efficiency and reduce costs. This can help to ensure that the parts produced are of the highest quality and will last for years to come.

The Advantages of Galvanized Steel Coils for Automotive Manufacturing

Galvanized steel coils are an essential component of automotive manufacturing. They provide superior corrosion resistance and strength, making them ideal for use in the automotive industry. Galvanized steel coils offer a number of advantages for automotive manufacturers, including:

1. Durability: Galvanized steel coils are highly durable and resistant to corrosion, making them ideal for use in the automotive industry. The galvanized coating helps protect the steel from rust and other forms of corrosion, ensuring that the parts last longer and perform better.

2. Strength: Galvanized steel coils are extremely strong and can withstand high levels of stress and strain. This makes them ideal for use in the automotive industry, where parts must be able to withstand the rigors of everyday use.

3. Cost-effectiveness: Galvanized steel coils are cost-effective, making them an attractive option for automotive manufacturers. The cost of galvanized steel coils is typically lower than other types of steel, making them a cost-effective choice for automotive manufacturers.

4. Versatility: Galvanized steel coils are highly versatile and can be used in a variety of applications. They can be used to create parts for a variety of vehicles, from cars to trucks to motorcycles. This makes them an ideal choice for automotive manufacturers who need to create parts for a variety of vehicles.

Galvanized steel coils are an essential component of automotive manufacturing. They provide superior corrosion resistance and strength, making them ideal for use in the automotive industry. Their cost-effectiveness, durability, and versatility make them an attractive option for automotive manufacturers.

The Benefits of Galvanized Steel Coils for Automotive Durability

Galvanized steel coils are an essential component of automotive durability. The process of galvanizing steel involves coating the metal with a layer of zinc, which provides a protective barrier against corrosion and other environmental damage. This layer of zinc helps to protect the steel from rust, corrosion, and other forms of damage, making it an ideal choice for automotive applications.

The galvanized steel coils used in automotive applications are typically made from high-grade steel, which is then coated with a layer of zinc. This layer of zinc helps to protect the steel from rust, corrosion, and other forms of damage. The zinc coating also helps to reduce the amount of friction between the steel and other components, which can help to reduce wear and tear on the vehicle.

The galvanized steel coils used in automotive applications are also highly durable. The zinc coating helps to protect the steel from corrosion and other environmental damage, making it an ideal choice for long-term use. The zinc coating also helps to reduce the amount of friction between the steel and other components, which can help to reduce wear and tear on the vehicle.

The galvanized steel coils used in automotive applications are also highly resistant to heat. The zinc coating helps to protect the steel from heat damage, making it an ideal choice for high-temperature applications. The zinc coating also helps to reduce the amount of friction between the steel and other components, which can help to reduce wear and tear on the vehicle.

The galvanized steel coils used in automotive applications are also highly resistant to abrasion. The zinc coating helps to protect the steel from abrasion damage, making it an ideal choice for applications that require a high level of durability. The zinc coating also helps to reduce the amount of friction between the steel and other components, which can help to reduce wear and tear on the vehicle.

Overall, galvanized steel coils are an essential component of automotive durability. The zinc coating helps to protect the steel from rust, corrosion, heat damage, and abrasion damage, making it an ideal choice for long-term use. The zinc coating also helps to reduce the amount of friction between the steel and other components, which can help to reduce wear and tear on the vehicle.

The Cost Savings of Galvanized Steel Coils for Automotive Manufacturing

Galvanized steel coils are an essential component of automotive manufacturing, providing strength and durability to the finished product. As such, it is important for automotive manufacturers to consider the cost savings associated with using galvanized steel coils in their production processes.

The cost savings associated with galvanized steel coils are numerous. First, galvanized steel coils are more cost-effective than other materials, such as aluminum or stainless steel. This is due to the fact that galvanized steel coils are more durable and require less maintenance over time. Additionally, galvanized steel coils are more resistant to corrosion, which can reduce the need for costly repairs and replacements.

In addition to cost savings, galvanized steel coils also offer a number of other benefits. For example, galvanized steel coils are lightweight, making them easier to transport and install. This can reduce the amount of time and labor required for installation, resulting in further cost savings. Additionally, galvanized steel coils are highly resistant to rust and other forms of corrosion, which can extend the life of the product and reduce the need for costly repairs and replacements.

Finally, galvanized steel coils are also highly recyclable, making them an environmentally friendly choice for automotive manufacturers. This can help to reduce the amount of waste generated during the manufacturing process, resulting in further cost savings.

Overall, galvanized steel coils offer a number of cost savings and other benefits to automotive manufacturers. By utilizing galvanized steel coils in their production processes, automotive manufacturers can reduce their costs and improve the quality of their products.

The Corrosion Resistance of Galvanized Steel Coils for Automotive Manufacturing

Galvanized steel coils are widely used in automotive manufacturing due to their superior corrosion resistance. Galvanized steel coils are coated with a layer of zinc, which acts as a barrier to protect the underlying steel from corrosion. The zinc coating also provides additional strength and durability to the steel, making it an ideal material for automotive components.

The corrosion resistance of galvanized steel coils is determined by the thickness of the zinc coating. The thicker the zinc coating, the greater the corrosion resistance. The zinc coating also needs to be applied in a uniform manner to ensure maximum protection. The zinc coating should also be applied in a manner that prevents the formation of zinc oxide, which can reduce the corrosion resistance of the steel.

The corrosion resistance of galvanized steel coils can also be improved by adding additional layers of protection. For example, a layer of paint or a clear coat can be applied over the zinc coating to provide additional protection against corrosion. Additionally, galvanized steel coils can be treated with a chromate conversion coating, which provides additional protection against corrosion.

In conclusion, galvanized steel coils are an ideal material for automotive components due to their superior corrosion resistance. The corrosion resistance of galvanized steel coils can be improved by increasing the thickness of the zinc coating and by adding additional layers of protection.

The Strength and Durability of Galvanized Steel Coils for Automotive Manufacturing

Galvanized steel coils are a popular choice for automotive manufacturing due to their strength and durability. Galvanized steel coils are made by coating a thin layer of zinc onto steel, which provides a protective layer that prevents corrosion and rust. This layer of zinc also increases the strength of the steel, making it more resistant to wear and tear.

The automotive industry requires materials that can withstand extreme temperatures, vibrations, and other environmental factors. Galvanized steel coils are able to meet these requirements due to their superior strength and durability. The zinc coating on the steel helps to protect it from corrosion and rust, while also increasing its strength. This makes it an ideal choice for automotive manufacturing, as it can withstand the harsh conditions of the automotive industry.

The strength and durability of galvanized steel coils also make them a cost-effective choice for automotive manufacturing. The zinc coating helps to reduce the cost of production, as it eliminates the need for additional protective coatings. Additionally, galvanized steel coils are easy to work with, making them a popular choice for automotive manufacturing.

Overall, galvanized steel coils are an ideal choice for automotive manufacturing due to their strength and durability. The zinc coating helps to protect the steel from corrosion and rust, while also increasing its strength. This makes it a cost-effective choice for automotive manufacturing, as it eliminates the need for additional protective coatings. Additionally, galvanized steel coils are easy to work with, making them a popular choice for automotive manufacturing.

The Versatility of Galvanized Steel Coils for Automotive Manufacturing

Galvanized steel coils are a versatile material for automotive manufacturing. They are used in a variety of applications, from body panels to structural components. Galvanized steel coils offer a number of advantages over other materials, including superior corrosion resistance, strength, and durability.

Galvanized steel coils are created by coating a thin layer of zinc onto steel. This layer of zinc acts as a barrier, protecting the steel from corrosion and other environmental damage. The zinc also provides additional strength and durability to the steel, making it an ideal material for automotive manufacturing.

Galvanized steel coils are used in a variety of automotive applications. They are often used for body panels, such as hoods, fenders, and doors. They are also used for structural components, such as frames, suspension components, and exhaust systems. Galvanized steel coils are also used for fuel tanks, fuel lines, and other fuel system components.

The corrosion resistance of galvanized steel coils makes them an ideal choice for automotive manufacturing. The zinc coating prevents rust and other forms of corrosion, ensuring that the components remain in good condition for years to come. The strength and durability of galvanized steel coils also make them an ideal choice for automotive manufacturing. The steel is strong enough to withstand the rigors of daily use, while also being lightweight enough to reduce the overall weight of the vehicle.

Galvanized steel coils are an ideal choice for automotive manufacturing due to their versatility, corrosion resistance, strength, and durability. They are used in a variety of applications, from body panels to structural components, and offer superior protection against corrosion and other environmental damage.

The Environmental Benefits of Galvanized Steel Coils for Automotive Manufacturing

Galvanized steel coils are increasingly being used in automotive manufacturing due to their environmental benefits. Galvanized steel coils are steel sheets that have been coated with a layer of zinc. This layer of zinc helps to protect the steel from corrosion and other forms of damage. The use of galvanized steel coils in automotive manufacturing has numerous environmental benefits.

First, galvanized steel coils are more durable than other types of steel, which means that they can last longer and require less frequent replacement. This reduces the amount of steel that needs to be produced and disposed of, which helps to reduce the environmental impact of the automotive industry.

Second, galvanized steel coils are more resistant to corrosion than other types of steel. This means that they can be used in a variety of environments without the need for additional protective coatings. This reduces the amount of chemicals that need to be used in the manufacturing process, which helps to reduce the environmental impact of the automotive industry.

Third, galvanized steel coils are recyclable. This means that they can be reused in the automotive industry, which helps to reduce the amount of waste that is produced. This helps to reduce the environmental impact of the automotive industry.

Finally, galvanized steel coils are more cost-effective than other types of steel. This means that they can be used in a variety of applications without the need for additional costs. This helps to reduce the overall cost of production, which helps to reduce the environmental impact of the automotive industry.

In conclusion, galvanized steel coils have numerous environmental benefits for automotive manufacturing. They are more durable, more resistant to corrosion, recyclable, and more cost-effective than other types of steel. These benefits help to reduce the environmental impact of the automotive industry.

Conclusion

In conclusion, galvanized steel coils offer a number of benefits for automotive manufacturing. They are cost-effective, durable, and corrosion-resistant, making them an ideal choice for automotive components. Additionally, galvanized steel coils are easy to work with and can be customized to meet specific needs. With all of these advantages, it is no wonder that galvanized steel coils are becoming increasingly popular in the automotive industry.