-

Table of Contents

- Introduction

- Analyzing the Cost Differences Between S355jr and S235JR Steel

- Investigating the Corrosion Resistance of S355jr and S235JR Steel

- Examining the Chemical Composition of S355jr and S235JR Steel

- Comparing the Mechanical Properties of S355jr and S235JR Steel

- Exploring the Structural Differences Between S355jr and S235JR Steel

“S355jr: Stronger, Lighter, and More Durable than S235jr!”

Introduction

The S355JR to S235JR are two different grades of steel that are used in a variety of applications. Both grades are made from a combination of iron and carbon, but the main difference between them is the amount of carbon present. The S355JR grade contains a higher amount of carbon, which gives it better strength and hardness properties than the S235JR grade. The S355JR grade is also more resistant to corrosion and wear than the S235JR grade. Both grades are widely used in the construction industry, but the S355JR grade is more commonly used for structural applications.

Analyzing the Cost Differences Between S355jr to S235JR Steel

When it comes to choosing the right steel for your project, it is important to consider the cost differences between S355jr to S235JR steel. Both of these steels are widely used in the construction industry, but they have different properties and costs. Knowing the differences between these two steels can help you make an informed decision when selecting the right steel for your project.

S355jr is a higher grade steel than S235JR, and is typically used in applications that require higher strength and durability. It is also more expensive than S235JR, as it has a higher carbon content and requires more processing. S355jr is often used in the construction of bridges, buildings, and other structures that require a high level of strength and durability.

S235JR is a lower grade steel than S355jr, and is typically used in applications that require less strength and durability. It is also less expensive than S355jr, as it has a lower carbon content and requires less processing. S235JR is often used in the construction of smaller structures, such as fences and sheds, as well as in the manufacturing of certain products.

When selecting the right steel for your project, it is important to consider the cost differences between S355jr and S235JR steel. Knowing the differences between these two steels can help you make an informed decision when selecting the right steel for your project. With the right steel, you can ensure that your project is built to last and that you get the most out of your investment.

Investigating the Corrosion Resistance of S355jr and S235JR Steel

The corrosion resistance of steel is an important factor to consider when selecting a material for a project. Steel is a popular choice for many applications due to its strength and durability, but it is also susceptible to corrosion. Two popular types of steel, S355JR and S235JR, are often used in construction and engineering projects. In this article, we will investigate the corrosion resistance of these two steels and discuss the implications for their use in projects.

S355JR is a low-alloy steel that is often used in construction and engineering projects. It has a higher yield strength than S235JR, making it more suitable for applications that require high strength. It also has a higher corrosion resistance than S235JR, making it a better choice for projects that require corrosion resistance.

S235JR is a carbon steel that is often used in construction and engineering projects. It has a lower yield strength than S355JR, making it less suitable for applications that require high strength. However, it has a higher corrosion resistance than S355JR, making it a better choice for projects that require corrosion resistance.

Both S355JR and S235JR have good corrosion resistance, but S235JR has a higher corrosion resistance than S355JR. This means that S235JR is a better choice for projects that require corrosion resistance. However, S355JR is a better choice for projects that require high strength.

When selecting a steel for a project, it is important to consider the corrosion resistance of the material. S355JR and S235JR are both popular choices for construction and engineering projects, but they have different corrosion resistance levels. S235JR has a higher corrosion resistance than S355JR, making it a better choice for projects that require corrosion resistance. However, S355JR is a better choice for projects that require high strength.

The corrosion resistance of steel is an important factor to consider when selecting a material for a project. S355JR and S235JR are both popular choices for construction and engineering projects, but they have different corrosion resistance levels. By understanding the differences between these two steels, you can make an informed decision about which material is best suited for your project. With the right material selection, you can ensure that your project is built to last.

Examining the Chemical Composition of S355jr and S235JR Steel

The chemical composition of steel is an important factor in determining its properties and performance. Steel is an alloy of iron and other elements, and the chemical composition of steel can vary depending on the grade and type of steel. Two of the most commonly used grades of steel are S355JR and S235JR.

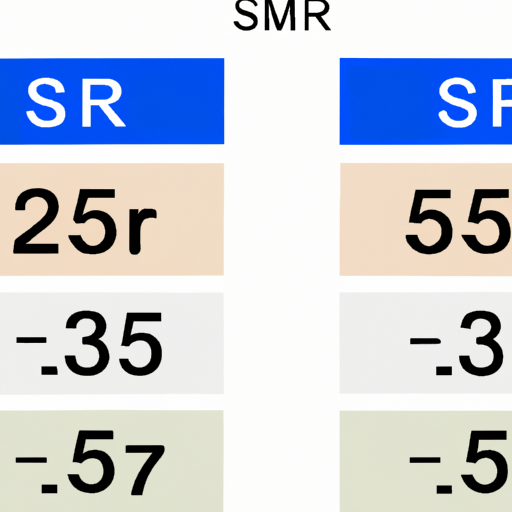

S355JR is a structural grade steel with a minimum yield strength of 355 N/mm². It is a non-alloy structural steel with a composition of 0.24% carbon, 1.60% manganese, 0.55% silicon, 0.03% phosphorus, 0.025% sulfur, 0.012% nitrogen, 0.47% aluminum, 0.20% chromium, 0.45% copper, 0.06% vanadium, 0.07% niobium, and 0.009% titanium.

S235JR is a non-alloy structural steel with a minimum yield strength of 235 N/mm². It has a composition of 0.17% carbon, 1.40% manganese, 0.55% silicon, 0.03% phosphorus, 0.025% sulfur, 0.012% nitrogen, 0.60% aluminum, 0.20% chromium, 0.45% copper, 0.06% vanadium, 0.07% niobium, and 0.009% titanium.

The chemical composition of these two grades of steel is quite similar, but the difference in their properties and performance is significant. S355JR is a higher strength steel with a minimum yield strength of 355 N/mm², while S235JR is a lower strength steel with a minimum yield strength of 235 N/mm². This difference in strength means that S355JR is more suitable for applications that require higher strength, such as construction and engineering projects.

The chemical composition of steel is an important factor in determining its properties and performance. S355JR and S235JR are two of the most commonly used grades of steel, and their chemical composition is quite similar. However, the difference in their properties and performance is significant, with S355JR being a higher strength steel with a minimum yield strength of 355 N/mm², while S235JR is a lower strength steel with a minimum yield strength of 235 N/mm². Understanding the chemical composition of steel can help you make the right choice for your project.

Comparing the Mechanical Properties of S355jr and S235JR Steel

When it comes to choosing the right material for a project, it is important to consider the mechanical properties of the material. Two of the most commonly used materials in the construction industry are S355JR and S235JR steel. Both of these materials have their own unique properties that make them suitable for different applications.

S355JR is a low-alloy, high-strength structural steel that is widely used in engineering and construction applications. It has excellent weldability and formability properties and offers good strength and toughness. It also has a higher yield strength than S235JR, making it ideal for applications that require high strength-to-weight ratios.

S235JR is a non-alloy structural steel that is widely used in the construction industry. It has good weldability and formability properties and offers good strength and toughness. It also has a lower yield strength than S355JR, making it suitable for applications that require lower strength-to-weight ratios.

When comparing the mechanical properties of S355JR and S235JR steel, it is important to consider the application for which the material will be used. S355JR is the better choice for applications that require high strength-to-weight ratios, while S235JR is the better choice for applications that require lower strength-to-weight ratios. Both materials offer excellent weldability and formability properties, making them suitable for a wide range of applications.

Exploring the Structural Differences Between S355jr to S235JR Steel

When it comes to structural steel, two of the most commonly used grades are S355JR to S235JR. Both of these grades are widely used in the construction industry, and they have some distinct differences that make them ideal for different applications.

The first difference between these two grades is in their chemical composition. S355JR is a low-carbon steel with a higher yield strength than S235JR. This means that it is more resistant to bending and buckling, making it ideal for structural applications. On the other hand, S235JR is a high-carbon steel with a lower yield strength, making it better suited for applications that require more flexibility.

The second difference between these two grades is in their mechanical properties. S355JR has a higher tensile strength than S235JR, making it better suited for applications that require more strength. It also has a higher yield strength, making it more resistant to deformation. On the other hand, S235JR has a lower tensile strength and a lower yield strength, making it better suited for applications that require more flexibility.

The third difference between these two grades is in their weldability. S355JR is more weldable than S235JR, making it easier to join two pieces of steel together. This makes it ideal for applications that require welding, such as bridges and buildings. On the other hand, S235JR is less weldable, making it better suited for applications that don’t require welding.

These are just a few of the structural differences between S355JR to S235JR steel. Both of these grades are widely used in the construction industry, and they each have their own unique properties that make them ideal for different applications. Whether you’re looking for a steel grade that is strong and resistant to deformation or one that is more flexible and weldable, these two grades can provide the perfect solution.