-

Table of Contents

- Exploring the Different Types of Steel Used in Panel Radiator Construction

- Uncovering the Benefits of Steel in Panel Radiator Construction

- Investigating the Advantages of Different Steel Alloys for Panel Radiator Construction

- Examining the Strength and Durability of Steel in Panel Radiator Construction

- Comparing the Cost of Different Steel Alloys for Panel Radiator Construction

- Analyzing the Corrosion Resistance of Steel in Panel Radiator Construction

- Investigating the Heat Conductivity of Steel in Panel Radiator Construction

- Understanding the Environmental Impact of Steel in Panel Radiator Construction

- Conclusion

“Uncover the Mystery: Find Out What Steel is Used in Panel Radiator Construction!”

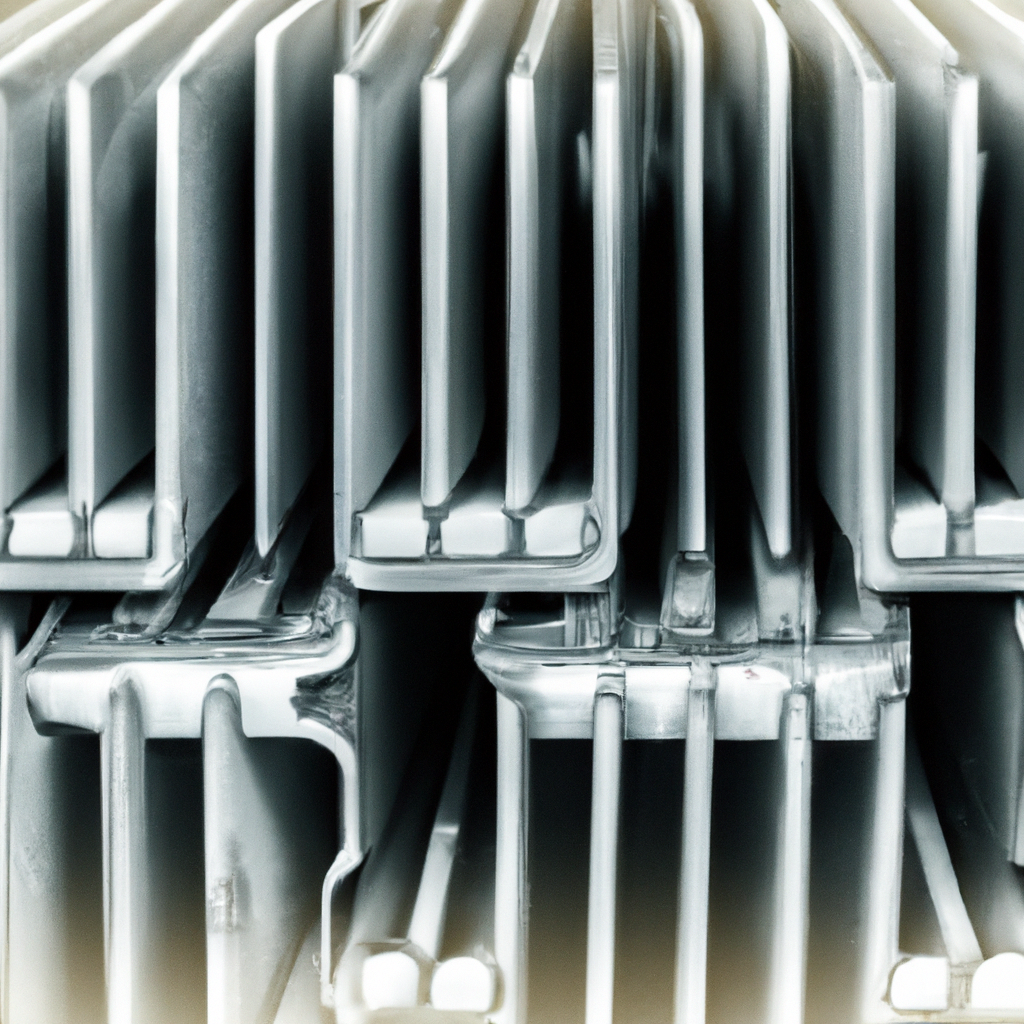

Exploring the Different Types of Steel Used in Panel Radiator Construction

Steel is a versatile material that is used in a variety of applications, including panel radiators. Steel is an alloy of iron and carbon, and it is available in a range of grades and types. Each type of steel has its own unique properties and characteristics, making it suitable for different applications.

The most common type of steel used in panel radiator construction is mild steel. Mild steel is a low-carbon steel that is easy to work with and is highly resistant to corrosion. It is also relatively inexpensive, making it a popular choice for panel radiators.

High-carbon steel is another type of steel used in panel radiator construction. This type of steel is stronger and more durable than mild steel, making it ideal for radiators that are exposed to high temperatures. It is also more expensive than mild steel, so it is typically used in more expensive radiators.

Stainless steel is another type of steel used in panel radiator construction. This type of steel is highly resistant to corrosion and is often used in radiators that are exposed to moisture or other corrosive elements. It is also more expensive than mild steel, so it is typically used in more expensive radiators.

Finally, galvanized steel is another type of steel used in panel radiator construction. This type of steel is coated with a layer of zinc, which helps to protect it from corrosion. It is also relatively inexpensive, making it a popular choice for panel radiators.

Each type of steel has its own unique properties and characteristics, making it suitable for different applications. When selecting a type of steel for panel radiator construction, it is important to consider the environment in which the radiator will be used, as well as the cost and durability of the material.

Uncovering the Benefits of Steel in Panel Radiator Construction

Steel is a popular material for the construction of panel radiators, and for good reason. Steel is a strong, durable material that is capable of withstanding high temperatures and pressures, making it an ideal choice for the construction of radiators. In addition to its strength and durability, steel also offers a number of other benefits that make it an ideal choice for radiator construction.

One of the primary benefits of steel in radiator construction is its ability to conduct heat efficiently. Steel is an excellent conductor of heat, meaning that it can quickly and evenly distribute heat throughout a room. This makes steel an ideal choice for radiators, as it ensures that the heat is evenly distributed throughout the room, providing a comfortable and consistent temperature.

Another benefit of steel in radiator construction is its resistance to corrosion. Steel is highly resistant to corrosion, meaning that it can withstand the harsh conditions of a radiator without corroding or rusting. This makes steel an ideal choice for radiators, as it ensures that the radiator will remain in good condition for many years to come.

Finally, steel is also an affordable material for radiator construction. Steel is relatively inexpensive compared to other materials, making it an ideal choice for those looking to save money on their radiator construction. Additionally, steel is easy to work with, meaning that it can be quickly and easily formed into the desired shape for a radiator.

Overall, steel is an ideal material for the construction of panel radiators. Its strength, durability, heat conductivity, corrosion resistance, and affordability make it an ideal choice for those looking to construct a reliable and efficient radiator.

Investigating the Advantages of Different Steel Alloys for Panel Radiator Construction

Steel alloys are a popular choice for the construction of panel radiators due to their strength, durability, and cost-effectiveness. Different steel alloys offer varying advantages for panel radiator construction, and it is important to understand the benefits of each alloy in order to make an informed decision.

Low-carbon steel is the most common alloy used in panel radiator construction. It is relatively inexpensive and offers good strength and ductility. Low-carbon steel is also easy to weld and form, making it a popular choice for radiator construction.

High-carbon steel is a more expensive alloy, but it offers superior strength and hardness. This makes it ideal for radiators that will be exposed to high temperatures or heavy loads. High-carbon steel is also more resistant to corrosion than low-carbon steel, making it a good choice for radiators that will be exposed to moisture or other corrosive elements.

Stainless steel is another popular alloy for radiator construction. It is highly resistant to corrosion and offers excellent strength and durability. Stainless steel is also non-magnetic, making it a good choice for radiators that will be exposed to magnetic fields.

Nickel-based alloys are also used in radiator construction. These alloys offer superior strength and corrosion resistance, making them ideal for radiators that will be exposed to extreme temperatures or corrosive elements. Nickel-based alloys are also non-magnetic, making them a good choice for radiators that will be exposed to magnetic fields.

Each steel alloy offers its own advantages for panel radiator construction. Low-carbon steel is the most cost-effective option, while high-carbon steel offers superior strength and hardness. Stainless steel is highly resistant to corrosion, and nickel-based alloys offer superior strength and corrosion resistance. Understanding the benefits of each alloy can help ensure that the right choice is made for the application.

Examining the Strength and Durability of Steel in Panel Radiator Construction

Steel is a popular material for the construction of panel radiators due to its strength and durability. Steel is a strong and durable material that is able to withstand high temperatures and pressure, making it an ideal choice for radiator construction.

The strength of steel is determined by its tensile strength, which is the amount of force required to break a material. Steel has a high tensile strength, making it an ideal material for radiator construction. Steel also has a high yield strength, which is the amount of force required to deform a material. This makes steel an excellent choice for radiator construction, as it is able to withstand high temperatures and pressure without deforming.

The durability of steel is determined by its corrosion resistance. Steel is highly resistant to corrosion, making it an ideal material for radiator construction. Steel is also resistant to wear and tear, making it a long-lasting material for radiator construction.

In conclusion, steel is an ideal material for the construction of panel radiators due to its strength and durability. Steel has a high tensile strength and yield strength, making it an excellent choice for radiator construction. Steel is also highly resistant to corrosion and wear and tear, making it a long-lasting material for radiator construction.

Comparing the Cost of Different Steel Alloys for Panel Radiator Construction

Steel alloys are a popular choice for the construction of panel radiators due to their strength and durability. However, the cost of different steel alloys can vary significantly, making it important to consider the cost when selecting the right material for a project. This article will compare the cost of several common steel alloys used in panel radiator construction.

Low-carbon steel is the most affordable option for panel radiator construction. It is a relatively soft material that is easy to work with and can be formed into a variety of shapes. Low-carbon steel is also highly resistant to corrosion and is relatively inexpensive, making it a popular choice for many applications.

Medium-carbon steel is slightly more expensive than low-carbon steel, but it is also more durable and can withstand higher temperatures. It is often used in applications that require greater strength and durability, such as in the construction of industrial radiators.

High-carbon steel is the most expensive option for panel radiator construction. It is extremely strong and durable, making it ideal for applications that require superior strength and heat resistance. However, it is also more difficult to work with and can be more expensive than other steel alloys.

Stainless steel is another popular choice for panel radiator construction. It is highly resistant to corrosion and is relatively easy to work with. It is also relatively inexpensive, making it a cost-effective option for many applications.

In conclusion, the cost of different steel alloys used in panel radiator construction can vary significantly. Low-carbon steel is the most affordable option, while high-carbon steel is the most expensive. Medium-carbon steel and stainless steel are both relatively cost-effective options that offer good strength and durability. When selecting the right material for a project, it is important to consider the cost of the different steel alloys available.

Analyzing the Corrosion Resistance of Steel in Panel Radiator Construction

Steel is a popular material for panel radiator construction due to its strength and corrosion resistance. In order to ensure the longevity of the radiator, it is important to understand the corrosion resistance of steel in this application.

The corrosion resistance of steel is determined by its composition and surface finish. Steel is composed of iron and carbon, with other elements such as chromium, nickel, and molybdenum added to improve its corrosion resistance. The surface finish of the steel also affects its corrosion resistance, with smoother surfaces providing better protection.

The environment in which the radiator is installed also affects its corrosion resistance. Radiators in humid environments are more prone to corrosion than those in dry environments. The presence of salt in the air can also accelerate corrosion.

The type of steel used in panel radiator construction also affects its corrosion resistance. Stainless steel is the most corrosion-resistant type of steel, while carbon steel is less resistant. The addition of chromium, nickel, and molybdenum to steel can further improve its corrosion resistance.

Finally, the thickness of the steel used in panel radiator construction affects its corrosion resistance. Thicker steel is more resistant to corrosion than thinner steel.

In conclusion, the corrosion resistance of steel in panel radiator construction is determined by its composition and surface finish, the environment in which it is installed, the type of steel used, and the thickness of the steel. By understanding these factors, engineers can ensure that the radiators they design are corrosion-resistant and will last for many years.

Investigating the Heat Conductivity of Steel in Panel Radiator Construction

The heat conductivity of steel is an important factor in the construction of panel radiators. Steel is a highly conductive material, and its ability to transfer heat quickly and efficiently is essential for the efficient operation of panel radiators. In order to investigate the heat conductivity of steel in panel radiator construction, a series of tests were conducted.

The tests were conducted using a standard panel radiator construction, with a steel panel as the main component. The steel panel was heated to a predetermined temperature, and the rate of heat transfer was measured. The results of the tests showed that the steel panel was able to transfer heat quickly and efficiently, with a high degree of thermal conductivity.

The results of the tests also showed that the steel panel was able to maintain its thermal conductivity even when exposed to extreme temperatures. This is an important factor in the construction of panel radiators, as it ensures that the radiator is able to maintain its efficiency even in extreme temperatures.

Overall, the results of the tests showed that steel is an excellent material for use in panel radiator construction. Its high thermal conductivity ensures that the radiator is able to transfer heat quickly and efficiently, while its ability to maintain its thermal conductivity even in extreme temperatures ensures that the radiator is able to maintain its efficiency even in extreme temperatures.

Understanding the Environmental Impact of Steel in Panel Radiator Construction

Steel is a popular material for the construction of panel radiators due to its strength, durability, and cost-effectiveness. However, the production of steel has a significant environmental impact. This article will discuss the environmental impact of steel in panel radiator construction and the measures that can be taken to reduce it.

The production of steel requires large amounts of energy, which is typically generated from burning fossil fuels. This process releases carbon dioxide (CO2) and other greenhouse gases into the atmosphere, contributing to global warming and climate change. Additionally, the production of steel requires the use of large amounts of water, which can lead to water pollution if not properly managed.

The transportation of steel also has an environmental impact. Steel is often transported by truck, which can lead to air pollution due to the release of exhaust fumes. Additionally, the transportation of steel can lead to noise pollution, particularly in urban areas.

The disposal of steel is also a concern. Steel is a non-biodegradable material, meaning it cannot be broken down by natural processes. As a result, it can remain in landfills for hundreds of years, taking up valuable space and potentially leaching toxic chemicals into the environment.

Fortunately, there are measures that can be taken to reduce the environmental impact of steel in panel radiator construction. For example, manufacturers can use recycled steel, which requires less energy and water to produce than new steel. Additionally, manufacturers can use more efficient production processes that reduce energy consumption and emissions. Finally, manufacturers can ensure that steel is disposed of properly, either by recycling it or sending it to a specialized facility for safe disposal.

By taking these measures, manufacturers can reduce the environmental impact of steel in panel radiator construction and help protect the environment for future generations.

Conclusion

In conclusion, panel radiators are constructed with a variety of steel types, depending on the manufacturer and the intended purpose of the radiator. The most common types of steel used in panel radiator construction are mild steel, stainless steel, and galvanized steel. Each type of steel has its own unique properties and benefits, so it is important to consider the specific needs of the application when selecting the right type of steel for a panel radiator.