-

Table of Contents

- How Galvanized Slitting is Revolutionizing the Manufacturing Industry

- Exploring the High-Tech Process Behind Galvanized Slitting

- A Comprehensive Guide to the Step-by-Step Process of Galvanized Slitting

- The Benefits of Galvanized Slitting for Industrial Applications

- The Latest Technologies Used in Galvanized Slitting

- Understanding the Different Types of Galvanized Slitting

- The Advantages of Automated Galvanized Slitting

- How to Achieve Optimal Results with Galvanized Slitting

- Conclusion

“Unlock the Power of Galvanized Slitting: A High-Tech Process Made Easy!”

How Galvanized Slitting is Revolutionizing the Manufacturing Industry

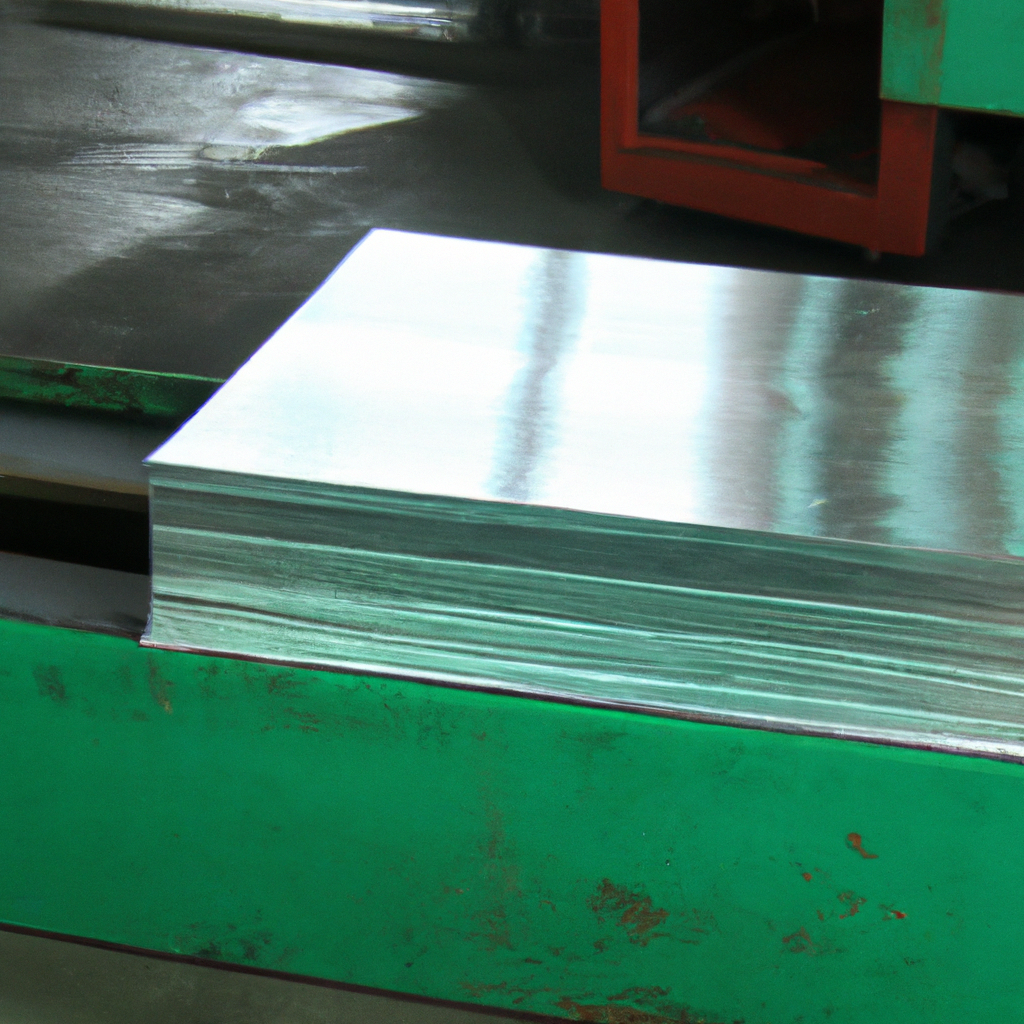

Galvanized slitting is revolutionizing the manufacturing industry by providing a cost-effective and efficient way to produce high-quality products. This process involves cutting a wide coil of galvanized steel into narrower strips of varying widths. The strips are then used to create a variety of products, such as roofing, siding, and other building materials.

The galvanized slitting process is highly efficient and cost-effective. It eliminates the need for multiple machines and processes, as the entire process can be completed in one step. This reduces the amount of time and money spent on production, allowing manufacturers to produce more products in less time. Additionally, the process produces a high-quality product with minimal waste.

The galvanized slitting process also offers a variety of benefits to manufacturers. It is a highly accurate process, allowing for precise cuts and measurements. This ensures that the products produced are of the highest quality and meet the exact specifications of the customer. Additionally, the process is highly efficient, allowing for faster production times and lower costs.

The galvanized slitting process is also highly versatile. It can be used to create a variety of products, from roofing and siding to other building materials. This allows manufacturers to create a wide range of products with minimal effort. Additionally, the process is highly customizable, allowing manufacturers to create products that meet the exact specifications of their customers.

Overall, galvanized slitting is revolutionizing the manufacturing industry by providing a cost-effective and efficient way to produce high-quality products. This process offers a variety of benefits to manufacturers, including increased accuracy, faster production times, and lower costs. Additionally, the process is highly versatile and customizable, allowing manufacturers to create a wide range of products with minimal effort. As a result, galvanized slitting is becoming an increasingly popular choice for manufacturers looking to produce high-quality products in an efficient and cost-effective manner.

Exploring the High-Tech Process Behind Galvanized Slitting

Galvanized slitting is a high-tech process used to cut metal into narrow strips. This process is used in a variety of industries, including automotive, construction, and aerospace. The process involves the use of specialized machinery and advanced techniques to ensure precise and accurate cuts.

The galvanized slitting process begins with the selection of the appropriate material. The material must be of the correct thickness and width to ensure a successful cut. Once the material is selected, it is placed on a slitting machine. The machine is equipped with a series of blades that are used to cut the material into strips. The blades are designed to cut the material with minimal waste and maximum accuracy.

The slitting machine is then programmed to cut the material into the desired widths. The machine is equipped with a series of sensors that detect the thickness of the material and adjust the cutting speed accordingly. This ensures that the strips are cut to the exact specifications.

Once the material is cut, it is then sent through a series of rollers. These rollers are designed to flatten the strips and ensure that they are of uniform thickness. The strips are then inspected for quality and accuracy. If any defects are found, they are corrected before the strips are sent for further processing.

The galvanized slitting process is an important part of many industries. It is a highly technical process that requires specialized machinery and advanced techniques to ensure precise and accurate cuts. By utilizing this process, manufacturers are able to produce high-quality products that meet the exact specifications of their customers.

A Comprehensive Guide to the Step-by-Step Process of Galvanized Slitting

Galvanized slitting is a process used to cut metal into narrow strips or coils. It is a common practice in the metal fabrication industry and is used to create components for a variety of applications. The process involves the use of a specialized machine, known as a slitter, to cut the metal into the desired widths. This guide will provide a step-by-step overview of the galvanized slitting process.

Step 1: Prepare the Metal

The first step in the galvanized slitting process is to prepare the metal for cutting. This involves cleaning the metal to remove any dirt, debris, or other contaminants that may interfere with the cutting process. The metal should also be inspected for any defects or irregularities that could affect the quality of the finished product.

Step 2: Set Up the Slitter

Once the metal is prepared, the slitter must be set up for the cutting process. This involves adjusting the machine’s settings to the desired widths and lengths of the strips or coils. The slitter should also be checked for any potential safety hazards or malfunctions that could affect the quality of the finished product.

Step 3: Feed the Metal into the Slitter

The next step is to feed the metal into the slitter. This is done by placing the metal onto the machine’s feed table and then using the machine’s controls to move the metal into the cutting area. The metal should be fed slowly and carefully to ensure that it is cut accurately and without any damage.

Step 4: Cut the Metal

Once the metal is in place, the slitter can begin cutting the metal into the desired widths and lengths. The slitter uses a series of blades to cut the metal into the desired shapes and sizes. The blades should be sharp and in good condition to ensure that the cuts are clean and precise.

Step 5: Remove the Cut Metal

Once the metal has been cut, it must be removed from the slitter. This is done by using the machine’s controls to move the metal away from the cutting area. The cut metal should then be inspected for any defects or irregularities that could affect the quality of the finished product.

Step 6: Finish the Product

The final step in the galvanized slitting process is to finish the product. This involves cleaning the metal to remove any burrs or sharp edges that may have been created during the cutting process. The metal should also be inspected for any defects or irregularities that could affect the quality of the finished product.

Galvanized slitting is an important process in the metal fabrication industry. By following this step-by-step guide, you can ensure that your metal is cut accurately and without any damage. With the right equipment and a little bit of practice, you can produce high-quality products with ease.

The Benefits of Galvanized Slitting for Industrial Applications

Galvanized slitting is a process used in industrial applications to cut metal into thin strips. This process is beneficial for a variety of reasons, including improved efficiency, cost savings, and improved product quality.

One of the primary benefits of galvanized slitting is improved efficiency. This process allows for the production of thin strips of metal quickly and accurately. This is especially beneficial for large-scale industrial applications, as it allows for the production of large quantities of metal strips in a short amount of time. Additionally, the process is highly automated, which further increases efficiency.

Another benefit of galvanized slitting is cost savings. This process is relatively inexpensive compared to other methods of cutting metal. Additionally, the process is highly efficient, which reduces the amount of time and labor required to produce the desired product. This can result in significant cost savings for industrial applications.

Finally, galvanized slitting can improve product quality. This process produces thin strips of metal with a high degree of accuracy. This ensures that the strips are uniform in size and shape, which is essential for many industrial applications. Additionally, the process produces strips with a smooth surface, which can reduce the amount of time and effort required to finish the product.

Overall, galvanized slitting is a beneficial process for industrial applications. This process is highly efficient, cost-effective, and produces high-quality strips of metal. As a result, it is an ideal choice for many industrial applications.

The Latest Technologies Used in Galvanized Slitting

Galvanized slitting is a process used to cut metal into narrow strips. It is a critical step in the production of many metal products, such as steel coils, sheets, and strips. To ensure the highest quality of the finished product, the latest technologies are used in galvanized slitting.

One of the most important technologies used in galvanized slitting is the use of computer numerical control (CNC) machines. CNC machines are computer-controlled machines that can accurately cut metal into narrow strips. They are programmed with the exact specifications of the desired product, and they can be adjusted to accommodate different materials and thicknesses. CNC machines are highly precise and can produce consistent results with minimal waste.

Another technology used in galvanized slitting is laser cutting. Laser cutting is a process that uses a laser beam to cut metal into narrow strips. It is a highly accurate and efficient process that can produce precise results with minimal waste. Laser cutting is also capable of cutting through thicker materials than CNC machines.

In addition to CNC and laser cutting, galvanized slitting also utilizes other technologies such as plasma cutting and waterjet cutting. Plasma cutting is a process that uses a high-temperature plasma arc to cut metal into narrow strips. It is a fast and efficient process that can produce precise results with minimal waste. Waterjet cutting is a process that uses a high-pressure stream of water to cut metal into narrow strips. It is a highly accurate and efficient process that can produce precise results with minimal waste.

The latest technologies used in galvanized slitting ensure that the finished product meets the highest quality standards. CNC machines, laser cutting, plasma cutting, and waterjet cutting are all used to ensure that the metal is cut into narrow strips with minimal waste and maximum precision.

Understanding the Different Types of Galvanized Slitting

Galvanized slitting is a process used to cut metal into narrow strips or coils. It is a common practice in the metal fabrication industry and is used to create components for a variety of applications. There are several different types of galvanized slitting, each with its own advantages and disadvantages.

The first type of galvanized slitting is called shear slitting. This method uses a shearing action to cut the metal into strips. The metal is placed between two blades and then the blades are forced together, cutting the metal into strips. This method is fast and accurate, but it can cause burrs and other imperfections in the metal.

The second type of galvanized slitting is called rotary slitting. This method uses a rotating blade to cut the metal into strips. The metal is placed between two blades and then the blades are rotated, cutting the metal into strips. This method is more accurate than shear slitting, but it can cause burrs and other imperfections in the metal.

The third type of galvanized slitting is called razor slitting. This method uses a razor blade to cut the metal into strips. The metal is placed between two blades and then the blades are forced together, cutting the metal into strips. This method is very accurate and produces a clean cut, but it can cause burrs and other imperfections in the metal.

The fourth type of galvanized slitting is called laser slitting. This method uses a laser beam to cut the metal into strips. The metal is placed between two blades and then the laser beam is used to cut the metal into strips. This method is very accurate and produces a clean cut, but it can be expensive and time consuming.

Each type of galvanized slitting has its own advantages and disadvantages. It is important to understand the different types of galvanized slitting and choose the one that best suits your needs.

The Advantages of Automated Galvanized Slitting

Automated galvanized slitting offers a number of advantages over manual slitting. Automated slitting is faster, more accurate, and more cost-effective than manual slitting.

Speed is one of the primary advantages of automated galvanized slitting. Automated slitting machines are capable of producing high-quality slits at speeds of up to 500 feet per minute. This is significantly faster than manual slitting, which can take up to several hours to complete. This increased speed allows for greater production efficiency and cost savings.

Accuracy is another advantage of automated galvanized slitting. Automated slitting machines are equipped with advanced sensors and controls that ensure precise and consistent slitting. This eliminates the need for manual measurements and adjustments, resulting in a higher quality product.

Cost savings is another benefit of automated galvanized slitting. Automated slitting machines require less labor and fewer materials than manual slitting. This reduces the cost of production and increases profitability. Additionally, automated slitting machines are designed to be more energy efficient than manual slitting, resulting in further cost savings.

Overall, automated galvanized slitting offers a number of advantages over manual slitting. It is faster, more accurate, and more cost-effective. Automated slitting machines are designed to be energy efficient and require less labor and materials, resulting in greater production efficiency and cost savings.

How to Achieve Optimal Results with Galvanized Slitting

Galvanized slitting is a process used to cut metal into narrow strips or coils. It is a cost-effective way to produce high-quality metal products. To achieve optimal results with galvanized slitting, it is important to follow certain best practices.

First, it is important to use the right type of slitting machine. Different types of machines are available, and each has its own advantages and disadvantages. It is important to select the right machine for the job, as this will ensure that the slitting process is efficient and produces high-quality results.

Second, it is important to use the correct blade for the job. Different blades are available for different types of materials, and it is important to select the right blade for the job. This will ensure that the slitting process is efficient and produces high-quality results.

Third, it is important to use the correct lubricant for the job. Different lubricants are available for different types of materials, and it is important to select the right lubricant for the job. This will ensure that the slitting process is efficient and produces high-quality results.

Fourth, it is important to use the correct tension for the job. Different tensions are available for different types of materials, and it is important to select the right tension for the job. This will ensure that the slitting process is efficient and produces high-quality results.

Finally, it is important to inspect the slitting process regularly. This will ensure that any problems are identified and addressed quickly, and that the slitting process is efficient and produces high-quality results.

By following these best practices, it is possible to achieve optimal results with galvanized slitting. It is important to select the right machine, blade, lubricant, and tension for the job, and to inspect the slitting process regularly. This will ensure that the slitting process is efficient and produces high-quality results.

Conclusion

The High-Tech Process Behind Galvanized Slitting: A Step-by-Step Guide provides a comprehensive overview of the process of galvanized slitting. It outlines the various steps involved, from the initial preparation of the material to the final product. The guide also explains the importance of quality control and safety measures to ensure the best results. By following the steps outlined in this guide, manufacturers can ensure that their galvanized slitting process is efficient and produces high-quality products.