ASTM Volume 01.06: Coated Steel Products

Author Archives: celikciler

ASTM Volume 01.05: Steel–Bars, Forgings, Bearing, Chain, Tool

ASTM Volume 01.04: Steel–Structural, Reinforcing, Pressure Vessel, Railway

ASTM Volume 01.02: Ferrous Castings; Ferroalloys

ASTM Steel–Piping, Tubing, Fittings

Hydrogen metallurgy processes Hydrogen metallurgy is a technique that uses hydrogen instead of carbon as a reduction agent to minimize CO2 emission. Because the use of hydrogen is advantageous to encouraging the sustainable growth of the steel industry, hydrogen metallurgy is a technology that reduces CO2 emission. hydrogen metallurgy of metals Hydrogen metallurgy has a […]

Production of steel from iron ore Ore containing iron The iron sprouts that were taken from the ground were analyzed, and the ones that had the most iron were listed below. > Magnetic > Hematite > Limonite > siderite > Pyrite Magnesite is a kind of mineral that has a naturally occurring magnetic field. Even […]

MECHANICAL ALLOY STEELS They are machine-made steels that are hardenable, particularly in terms of carbon content, and exhibit high toughness at a specified tensile strength at the conclusion of the curing process. Different machinery and engine components, forging parts, various bolts, nuts and studs, crankshafts, axles, control and drive parts, piston rods, various shafts, gears, […]

NON-ALLOY MECHANIC STEELS Generally, in a large part of machine production without improvement; axles, ship supplies, They are used in making bolts, nuts etc. Types with a C limit above 0.40 are also used by induction hardening. Source : Link

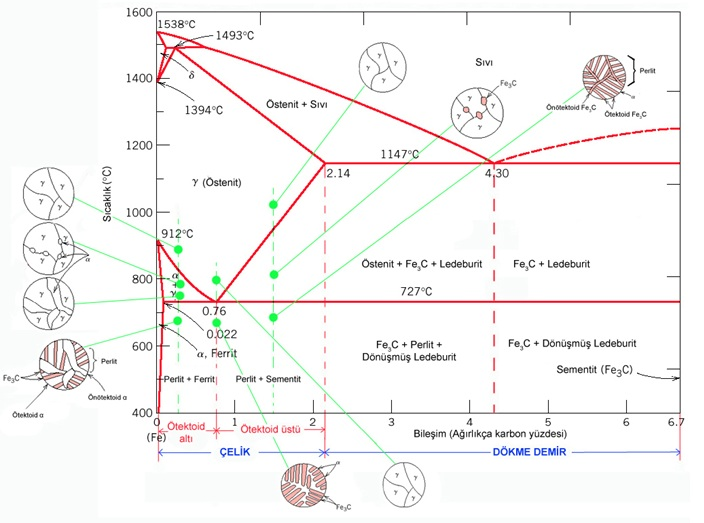

Steel and steel alloy elements are defined as: It is an iron-carbon alloy called steel. Small amounts of silicon, manganese, sulfur, and phosphorus are included in this alloy. These sums are typically: from 0.1 to 1.7 (rarely 2%) Carbon (C) (C) 0.15 – 0.40% Silicon (SI) (SI) 0.40% – 0.80% Manganese […]